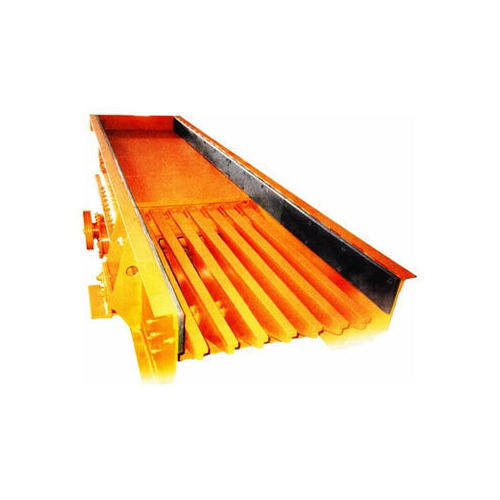

Grizzly Feeder

Product Details:

- Rotation Type Linear / Reciprocating motion

- Control System Automatic/Manual

- Belt Type Not Used (uses grizzly bar plate)

- Features Low Maintenance, High Efficiency

- Equipment Type Grizzly Feeder

- Motor Type Heavy Duty Vibratory Motor

- Condition New

- Click to view more

Grizzly Feeder Price And Quantity

- Varies by model

- Mining, Stone Crushing, Aggregate Screening

- Painted/Coated for Corrosion Resistance

- Single or Double Deck

- High-Grade Steel, Manganese Steel Bars

- Adjustable

- Up to 900 mm

- -10°C to +50°C

- Fixed, Skid Mounted or Mobile

- As per requirement / Model Specific

- 50 to 600 TPH

- Low

- Direct/Indirect Drive

Grizzly Feeder Product Specifications

- Up to 600 TPH

- Automatic/Manual

- Linear / Reciprocating motion

- New

- 3-15 HP (varies with model)

- Heavy Duty Vibratory Motor

- Electric

- Low Maintenance, High Efficiency

- Grizzly Feeder

- Pre-screening of fines, Improved feed rate, Resistant to abrasion

- Not Used (uses grizzly bar plate)

- Heavy-Duty, Adjustable Grizzly Bars, Robust Construction

- 220/380/415 V (customizable)

- Varies by model

- Mining, Stone Crushing, Aggregate Screening

- Painted/Coated for Corrosion Resistance

- Single or Double Deck

- High-Grade Steel, Manganese Steel Bars

- Adjustable

- Up to 900 mm

- -10°C to +50°C

- Fixed, Skid Mounted or Mobile

- As per requirement / Model Specific

- 50 to 600 TPH

- Low

- Direct/Indirect Drive

Product Description

Carbon steel or 304 grade stainless steel made Grizzly Feeder is a type of electromagnetic vibration feeder that has extensive applications in construction, metallurgy, chemical and mining arena. This feeder is required for feeding bulk materials (granular and powder based) from storage bin to other receiving system by maintaining consistency and homogeneity in distribution. Available in single phase design, this Grizzly Feeder has linear type structure that simplifies its installation process. This system is a type of electromagnetic vibration feeding solution that generates minimal noise. Being light in weight, its handling procedure is hassle free. Excellent operating frequency and precision in automatic controlling are some of the main aspects of this equipment.

Product details

| Model No | MGF 0803 |

| Size | 8 x 3 Feet (L x W) |

| Material Property | Corrosive |

| Power | 3.0 HP - 2 Nos. |

| Brand | Moderate |

| Usage/Application | Industrial |

| Capacity | 25- 50 T.P.H |

| Lifting Capacity | 2 Ton |

Versatile Design & Robust Build

Featuring a choice of single or double deck, the Grizzly Feeder is engineered for versatility. The adjustable grizzly bars enable precise control over material separation, enhancing feed rate and reducing downstream wear. Its robust construction, with options for both fixed and mobile installation, ensures reliable service in challenging industrial conditions.

Efficient Pre-Screening and Material Handling

The feeder excels in removing fines before material enters crushers, thanks to its adjustable bar gap system. This not only optimizes crusher efficiency but also minimizes equipment wear and maintenance costs. The heavy-duty vibratory motor delivers efficient performance with linear or reciprocating motion for consistent feed transfer.

Low Maintenance & High Efficiency

Engineered for low noise and minimized maintenance requirements, the Grizzly Feeder incorporates heavy-duty parts and automated/manual control options. Its surface treatment resists corrosion, supporting longevity and stable operation across a wide temperature range, from -10C to +50C.

FAQ's of Grizzly Feeder:

Q: How does the Grizzly Feeder improve the efficiency of stone crushing and aggregate operations?

A: The Grizzly Feeder pre-screens fines by separating smaller particles before material enters the primary crusher. This optimizes crusher performance, reduces equipment wear, and improves the overall feed rate, making the process more efficient and minimizing maintenance expenses.Q: What installation types are available for the Grizzly Feeder?

A: The Grizzly Feeder can be installed as a fixed unit, skid-mounted, or on a mobile structure. This flexibility allows integration into various plant layouts and operational needs, whether for permanent facilities or portable setups.Q: Where is the Grizzly Feeder typically used?

A: This equipment is widely used in mining, quarrying, stone crushing plants, and aggregate screening facilities. Its robust design and adaptability make it suitable for handling heavy-duty materials in demanding environments.Q: What advantages come from using manganese steel bars in the feeder's construction?

A: Manganese steel bars offer exceptional durability and resistance to abrasion, ensuring the feeder withstands the impacts of large, abrasive materials. This extends the service life of the equipment and reduces replacement frequency.Q: When should the adjustable bar gap on the Grizzly Feeder be modified?

A: Adjust the bar gap when there are changes in the size distribution of incoming material or when optimizing for different types of feed requirements. This allows operators to fine-tune pre-screening, maximizing efficiency and protecting downstream equipment.Q: How does the control system in the Grizzly Feeder operate?

A: The feeder features both automatic and manual control systems. Operators can select the mode depending on operational needs, allowing for flexible, responsive adjustment of feed rates and scheduling routine maintenance easily.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Vibro and Grizzly Feeder' category

|

MODERATE ENGINEERING (PVT) LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |