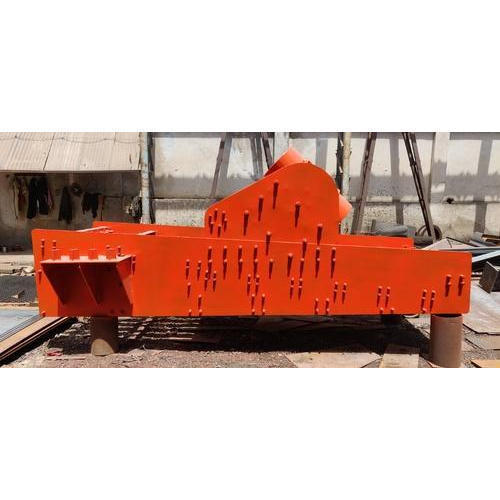

Vibro Feeder

Product Details:

- Belt Type No belt Tray type

- Features Silent operation, Easy installation

- Control System Electronic controller

- Motor Type Vibratory motor

- Rotation Type Linear vibration

- Equipment Type Feeder

- Condition New

- Click to view more

Vibro Feeder Price And Quantity

- Powder coated/painted

- Custom built (typically 600 mm to 1500 mm length)

- -10°C to 50°C

- Adjustable up to 2 tons per hour

- Base mounted

- Industrial feeding, Packaging, Conveying

- Mild steel / stainless steel

- Provided

- Adjustable

- Bulk material handling

- 50/60 Hz

Vibro Feeder Product Specifications

- 0.5 to 2 kW

- 230 V AC

- Adjustable feed rate, Robust construction

- New

- 500 kg (approx.)

- Linear vibration

- Vibratory motor

- Feeder

- Up to 500 kg/hr

- Electric

- No belt Tray type

- Continuous feeding, Low maintenance

- Silent operation, Easy installation

- Customizable as per requirement

- Electronic controller

- Powder coated/painted

- Custom built (typically 600 mm to 1500 mm length)

- -10°C to 50°C

- Adjustable up to 2 tons per hour

- Base mounted

- Industrial feeding, Packaging, Conveying

- Mild steel / stainless steel

- Provided

- Adjustable

- Bulk material handling

- 50/60 Hz

Product Description

Featured with electromagnetic mechanism, this Vibro Feeder is suitable for transferring bulk materials ( granular, solid and powder based substances) under vibratory force. Vibration force applied for its functioning produces vertical as well as horizontal acceleration to handled materials. Gravity based force produced due to vibration promotes movement of conveyed materials to a specific direction. Vibro Feeder is well known for its low power consumption, reliable mechanism, low production cost, minimal noise generation and trouble free maintenance. Its enclosed type structure reduces environmental pollution. Standard of this system has been verified as per its output, mode of action, operating cost and life span.

Product details

| Feeding Capacity | 50- 100 TPH |

| Model | MVS-620 |

| No. of Layers | 2-4 |

| Size L x W | 6100X 1825 mm |

| Material | Mild Steel |

| Material Property | Corrosive |

| Rotating Speed | 900 RPM |

| Power | 25.0 HP |

| Brand | Moderate |

| Usage/Application | Industrial |

| Lifting Capacity | 8 Ton |

Robust and Versatile Bulk Handling Solution

Engineered to handle a wide range of bulk materials, the Vibro Feeder features an adjustable feed rate, customizable tray length, and mounting options to fit varied operational needs. Its robust construction with both mild steel and stainless steel choices ensures durability, while powder-coated finishes protect against wear, supporting long-term performance in challenging industrial environments.

Precision Control for Efficient Operations

Equipped with an electronic controller, this feeder allows for fine-tuning of feed rates and amplitude, accommodating material flow requirements from low to high throughput, up to 2 tons per hour. The silent operation, efficient vibratory motor, and maintenance-friendly design make it ideal for continuous industrial feeding, packaging, and conveying tasks.

FAQ's of Vibro Feeder:

Q: How does the Vibro Feeder ensure consistent and controlled feeding of materials?

A: The Vibro Feeder operates with a vibratory motor and linear vibration mechanism, providing continuous and even material flow. The feed rate and amplitude are adjustable through an electronic controller, allowing for precise control based on material characteristics and process needs.Q: What are the primary applications of this Vibro Feeder in industrial settings?

A: This feeder is widely used in applications such as industrial feeding, packaging, and conveying bulk materials. Its robust build and customizable tray make it suitable for industries that require reliable, continuous material handling processes.Q: When should I choose a stainless steel tray over a mild steel one for my Vibro Feeder?

A: Stainless steel trays are recommended when handling corrosive or hygiene-sensitive materials, such as in food processing or chemical industries. Mild steel is suitable for general industrial applications where such concerns are minimal.Q: Where should the Vibro Feeder be installed for optimal performance?

A: The feeder is base-mounted, making it ideal for stable floor installations near material infeed or processing points. It is designed to be easily integrated within new or existing bulk handling lines in industrial facilities.Q: What process controls are included with the Vibro Feeder?

A: An electronic control panel comes with the feeder, enabling operators to adjust the feed rate and amplitude to match process requirements. This ensures efficient material handling and minimizes manual intervention.Q: What are the key benefits of using a Vibro Feeder for bulk material handling?

A: Key benefits include adjustable feed rates, silent operation, low maintenance, easy installation, and the ability to handle a wide temperature range. These features contribute to reliable, cost-effective, and efficient bulk material conveying in industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Vibro and Grizzly Feeder' category

|

MODERATE ENGINEERING (PVT) LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |